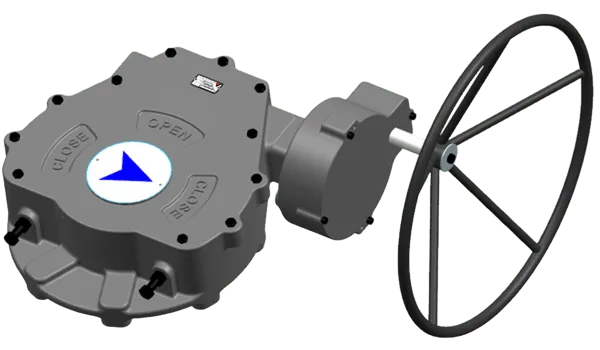

Butterfly Valve Gearbox for Reliable Industrial Valve Operations

Industrial flow control systems demand precision, durability, and consistent performance. In such systems, a Butterfly Valve Gearbox plays a critical role by ensuring smooth valve movement and controlled torque transmission. Designed to operate butterfly valves efficiently, this mechanical unit enhances safety, accuracy, and operational ease across multiple industries.

At Jayveer Enterprise, high-quality gearbox solutions are developed to meet the demanding requirements of modern industrial applications. With robust construction and reliable engineering, these gearboxes are built to perform in challenging environments where performance cannot be compromised.

Butterfly Valve Gearbox Function and Working Principle Explained

A butterfly valve gearbox is used to reduce the manual effort required to open and close large-sized butterfly valves. It works by converting rotational input into controlled torque output, allowing precise valve positioning. This mechanism ensures that the valve disc rotates smoothly without sudden movement or excessive force.

In industrial pipelines, where pressure and flow rates vary, accurate control is essential. A properly engineered gearbox maintains steady operation while protecting the valve stem from damage. This balance between power and precision makes the gearbox an essential component in valve automation and manual operation systems.

Butterfly Valve Gearbox Design for Industrial Durability

The design of a butterfly valve gearbox focuses on strength, corrosion resistance, and long-term reliability. Manufactured using high-grade materials, the gearbox casing protects internal components from dust, moisture, and chemical exposure. This design ensures stable performance even in harsh industrial conditions. Jayveer Enterprise emphasizes precision machining and quality assembly to deliver gearboxes that operate smoothly over extended periods. The internal gear arrangement minimizes backlash and wear, which directly contributes to improved valve life and reduced maintenance requirements.

Butterfly Valve Gearbox Types Used in Various Applications

Different industries require different gearbox configurations based on valve size, operating torque, and installation conditions. A butterfly valve gearbox is available in multiple types, including worm gear, bevel gear, and spur gear mechanisms. Each type offers specific advantages depending on the application.

Worm gear models are commonly used for high-torque applications where self-locking is required. Bevel gear designs are suitable for compact installations, while spur gear options offer efficient torque transfer in moderate load conditions. Selecting the right gearbox type ensures optimal valve control and system efficiency.

Butterfly Valve Gearbox Applications Across Industries

A butterfly valve gearbox is widely used in industries such as water treatment, oil and gas, chemical processing, power generation, and HVAC systems. In water distribution networks, it enables smooth regulation of flow in large pipelines. In chemical plants, precise valve control ensures safety and process accuracy.

Power plants rely on these gearboxes to manage steam and cooling water flow efficiently. Similarly, HVAC systems use them to control air and fluid movement in commercial and industrial buildings. The versatility of this gearbox makes it suitable for both manual and automated valve systems.

Butterfly Valve Gearbox Advantages in Flow Control Systems

One of the major benefits of using a butterfly valve gearbox is improved operational safety. By reducing manual force, the gearbox prevents sudden valve movement and minimizes operator fatigue. This controlled operation reduces the risk of system damage and ensures consistent flow regulation.

Another advantage is extended valve lifespan. Smooth torque transmission reduces stress on valve components, leading to lower wear and tear. With proper installation and maintenance, the gearbox contributes to long-term system reliability and reduced downtime.

Butterfly Valve Gearbox Selection Factors for Buyers

Choosing the right butterfly valve gearbox requires careful consideration of several factors. Valve size, operating pressure, torque requirement, and environmental conditions all play an important role. A gearbox must be compatible with the valve specifications to ensure efficient performance.

Material selection is also critical, especially in corrosive or high-temperature environments. Jayveer Enterprise offers gearbox solutions designed to meet diverse industrial needs, ensuring compatibility, durability, and ease of operation for various applications.

Butterfly Valve Gearbox Maintenance and Performance Reliability

Regular maintenance helps maintain the efficiency of a butterfly valve gearbox. Proper lubrication, periodic inspection, and alignment checks ensure smooth operation and prevent unexpected failures. A well-maintained gearbox delivers consistent torque output and accurate valve positioning.

High-quality manufacturing reduces the frequency of maintenance and enhances overall system reliability. By investing in durable gearboxes, industries can achieve uninterrupted operations and long-term cost savings.

Butterfly Valve Gearbox Solutions by Jayveer Enterprise

Jayveer Enterprise specializes in delivering dependable industrial gearbox solutions that meet international quality standards. With a focus on engineering excellence, the company provides products designed for performance, safety, and longevity.

Each gearbox undergoes strict quality checks to ensure smooth operation and dimensional accuracy. This commitment to quality makes Jayveer Enterprise a trusted name for industrial flow control components.

Butterfly Valve Gearbox Conclusion for Industrial Use

A butterfly valve gearbox is an essential component for achieving precise and reliable valve control in industrial systems. Its ability to manage torque, enhance safety, and improve operational efficiency makes it indispensable across multiple sectors.

By choosing well-engineered solutions from Jayveer Enterprise, industries can ensure smooth valve operation, extended equipment life, and consistent process control. Investing in the right gearbox ultimately leads to improved performance and dependable flow regulation in demanding industrial environments.