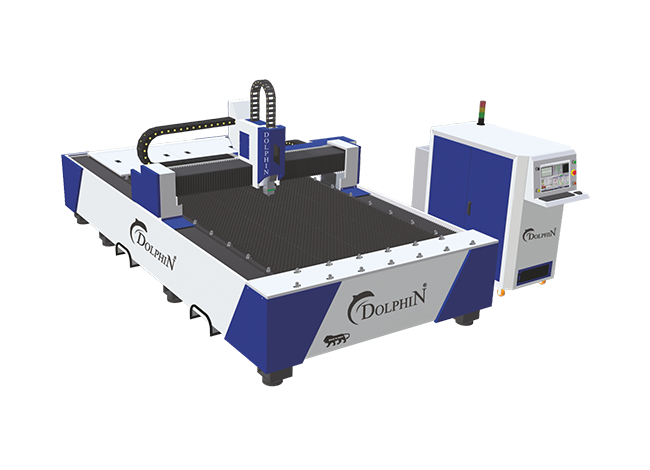

Fiber Laser Cutting Machine for Advanced Metal Cutting Solutions

Modern manufacturing industries require speed, precision, and reliability to remain competitive. A Fiber Laser Cutting Machine has become one of the most preferred technologies for metal processing due to its efficiency and accuracy. This advanced system supports high-speed cutting while maintaining excellent edge quality. Laser Machine Manufacturers continue to enhance this technology to meet the evolving demands of industrial production.

Fiber Laser Cutting Machine Technology Overview

A Fiber Laser Cutting Machine uses a solid-state laser source that generates a highly concentrated beam through optical fiber. This beam allows precise cutting of metals with minimal heat distortion. Unlike traditional cutting methods, fiber laser technology offers better energy efficiency and longer operational life.

Manufacturers benefit from stable beam quality and reduced maintenance requirements. Laser Machine Manufacturers focus on improving laser sources and control systems to ensure consistent performance across different industrial applications.

Fiber Laser Cutting Machine for Metal Fabrication Industry

Metal fabrication industries rely heavily on accuracy and speed. In such environments, a Fiber Laser Cutting Machine delivers consistent results across large production volumes. The non-contact cutting process reduces mechanical stress on materials, resulting in clean and smooth edges.

Industries such as automotive, aerospace, construction, and electronics widely adopt this technology. Laser Machine Manufacturers design machines that support continuous production without compromising quality.

Fiber Laser Cutting Machine Material Handling Capabilities

Material versatility is a key advantage in modern manufacturing. A Fiber Laser Cutting Machine processes stainless steel, mild steel, aluminum, copper, brass, and alloy metals efficiently. This flexibility allows manufacturers to manage diverse projects using a single machine setup.

Different thickness levels can be handled with precision, reducing the need for multiple cutting systems. Laser Machine Manufacturers ensure machines are optimized for stable performance across various metal types.

Fiber Laser Cutting Machine Precision and Cutting Accuracy

Precision is critical in metal component manufacturing. A Fiber Laser Cutting Machine ensures accurate cuts with narrow kerf widths and minimal material loss. Advanced motion control systems maintain cutting consistency even during complex design execution.

Improved software integration further enhances accuracy by synchronizing laser power and cutting speed. Laser Machine Manufacturers invest in intelligent control solutions to support detailed and intricate metal designs.

Fiber Laser Cutting Machine Boosting Production Efficiency

High productivity is essential for large-scale manufacturing units. A Fiber Laser Machine significantly reduces processing time compared to conventional cutting methods. Automated loading and unloading systems further streamline workflow efficiency.

Lower energy consumption contributes to reduced operational costs. Laser Machine Manufacturers design machines that balance high output with energy-efficient operation, making them suitable for long-term industrial use.

Fiber Laser Cutting Machine Safety and Automation Features

Workplace safety remains a top priority in manufacturing units. A Fiber Laser Cutting Machine includes protective enclosures, real-time monitoring, and emergency stop functions. These features ensure safe operation during high-speed cutting processes.

Automation minimizes manual handling, reducing operator fatigue and error. Laser Machine Manufacturers integrate user-friendly interfaces that allow precise control and monitoring of cutting parameters.

Fiber Laser Cutting Machine Supporting Custom Metal Designs

Customization plays a growing role in modern metal fabrication. A Fiber Laser Cutting Machine allows manufacturers to modify designs quickly without additional tooling costs. This flexibility supports small-batch production and customized components.

Seamless compatibility with CAD and CAM software enables smooth design transitions. Laser Machine Manufacturers focus on digital integration to support creative flexibility and production accuracy.

Fiber Laser Machine Maintenance and Operational Reliability

Operational reliability is essential for maintaining production schedules. A Fiber Laser Cutting Machine requires minimal maintenance due to fewer moving parts and solid-state laser technology. Routine checks ensure stable performance and extended machine lifespan.

Efficient cooling systems and durable components reduce downtime. Laser Machine Manufacturers emphasize robust construction to support demanding industrial environments.

Fiber Laser Cutting Machine Contribution to Sustainable Manufacturing

Sustainability has become an important consideration for manufacturers worldwide. A Fiber Laser Cutting Machine supports eco-friendly production by minimizing waste and reducing energy consumption. Precision cutting ensures optimal material utilization.

Laser Machine Manufacturers continue to develop energy-efficient systems that align with sustainable manufacturing goals. These advancements help businesses lower their environmental footprint while maintaining high productivity.

Fiber Laser Cutting Machine as a Strategic Industrial Investment

Choosing a Fiber Laser Cutting Machine is a strategic move for businesses focused on growth and efficiency. The machine enhances production capabilities, improves quality standards, and reduces operating costs. Its ability to handle diverse materials makes it a valuable asset for metal fabrication units.

Laser Machine Manufacturers remain committed to innovation, delivering advanced fiber laser solutions that meet modern industrial requirements. Investing in a Fiber Laser Machine ensures long-term productivity and positions businesses for future success.